Ultrasonic horns are devices used to amplify the vibration amplitudes provided by ultrasonic transducers and deliver the acoustic energy to the processed liquids. ISM supplies several types of high-efficiency ultrasonic horns as parts of its laboratory, bench and industrial-scale liquid processors.

For detailed information download our

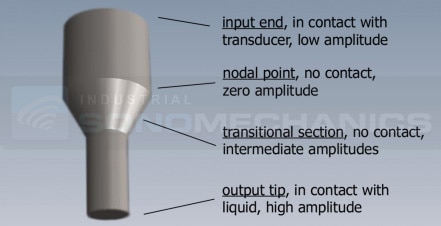

Conventional Horn

- suitable for small-scale process investigations.

- Able to provide very high ultrasonic amplitudes and power densities,

- cannot deliver significant amounts of total power to liquids because their output tip diameters are small, which limits cavitation zone volumes they are able to generate

- not appropriate for commercial-scale liquid processing, but are recommended for laboratory-scale data collection prior to scale-up.

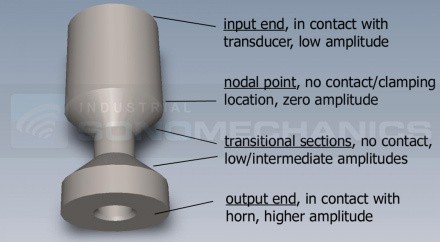

Full-Wave Barbell Horn (FBH)

- Process scale-up requires switching to horns with larger output tip diameters, able to output the ultrasonic energy into greater volumes of working liquids while still maintaining high amplitudes.

- appropriate for large-scale batch liquid processing and investigations.

- can have large output tip diameters (up to about 60 mm)

- able to generate very high ultrasonic amplitudes and power densities, creating large cavitation zones and delivering substantial amounts of power to liquids.

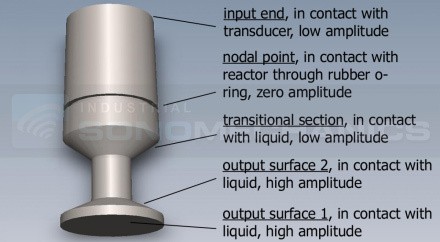

Half-Wave Barbell Horn (HBH)

- ideal for industrial-scale flow-through liquid processing.

- can have large output tip diameters (up to about 50 mm)

- generate high ultrasonic amplitudes and power densities, creating large cavitation zones and delivering very high power to liquids.

- produce two major cavitation zones (under and above the output section) ensuring that no liquid is able to bypass the active treatment zone as it flows through the reactor chamber.

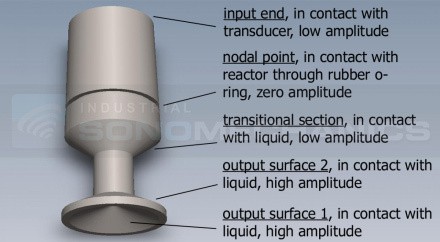

Half-Wave Barbell Horn with an Opening (HBHO)

- the right choice for industrial-scale flow-through liquid processing where extremely high power deposition is required.

- can have large-diameter output sections and generate high ultrasonic amplitudes and power densities, creating very large cavitation zones and delivering extremely high power to liquids.

- output surface areas of these devices are further increased by hollow regions in their output sections.

Half-Wave Barbell Booster (HBB)

- can be connected between a transducer and a horn to modify the horn’s effective gain factor (amplify or reduce).

- gain (when used as an amplifier, as shown on the left) or reduction (when connected in the opposite direction) factor should be multiplied by the horn’s gain factor to obtain the resulting assembly’s gain factor.

- can also be used as assembly length extenders and to provide additional clamping support.