Ultrasonic degassing is an efficient method of removing dissolved gasses and/or entrained gas bubbles from a variety of liquids. Unlike vacuum degassing, which is a batch approach, ultrasonic degassing can be done in a continuous-flow mode.

Overview

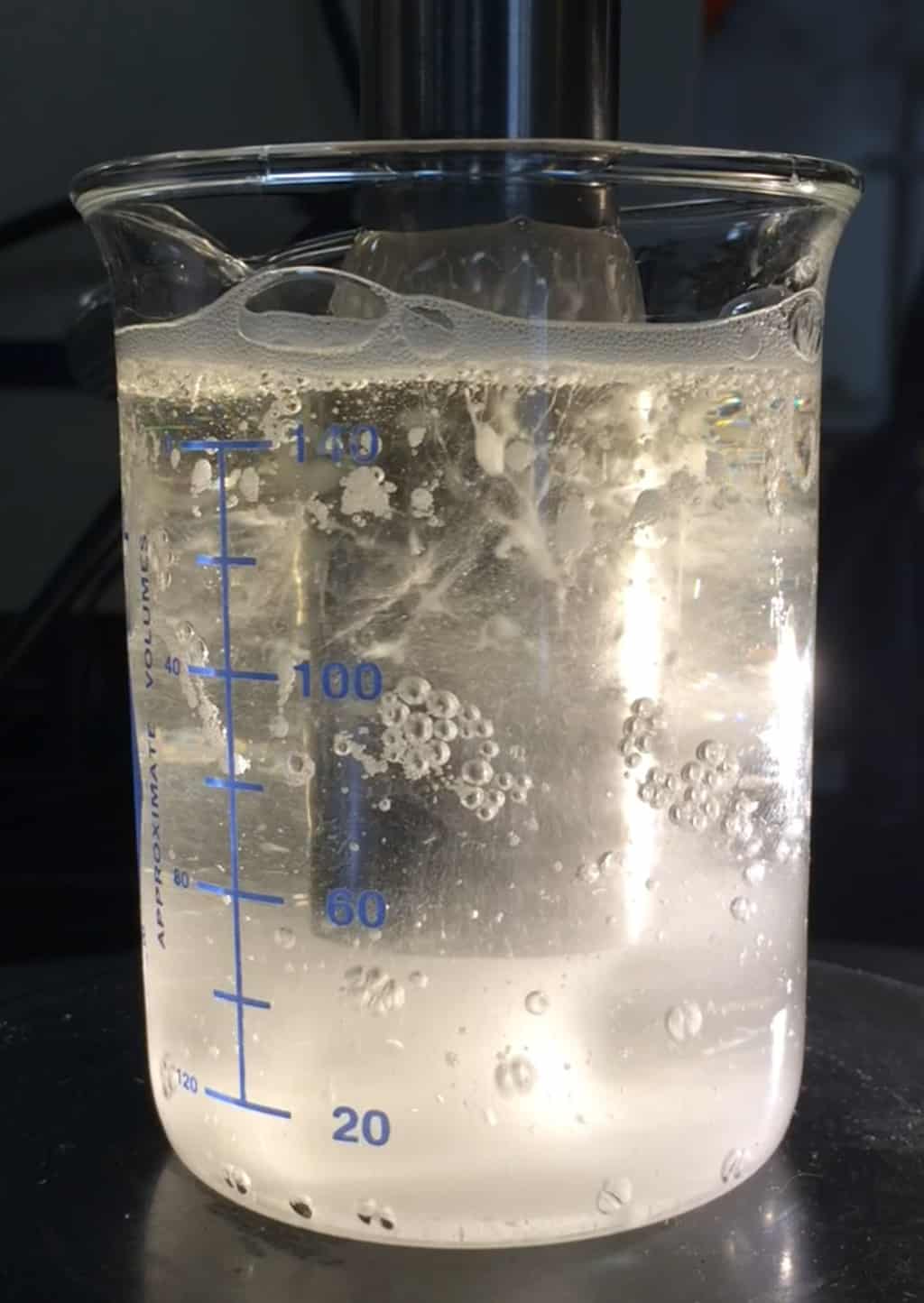

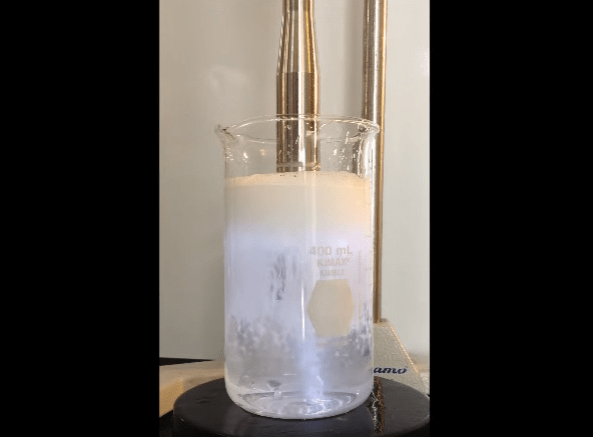

Ultrasonic degassing (deaeration, in the case of air) is an efficient method of removing dissolved gasses and/or entrained gas bubbles from a variety of liquids, including water, candle waxes, aluminum alloy melts, epoxies, silicone oils, adhesives, coating solutions, beverages, polymers, inks, paints, transformer oils, emulsion and suspension products, motor oils and many more. Unlike vacuum degassing, which is a batch approach, ultrasonic degassing can be done in a continuous-flow mode.

Case Studies & Application Reports

Ultrasonic Degassing and Deaeration

Blog Posts

03/19/16

Removing Air From Oils, Epoxies, Hydraulic Fluids, Adhesives, Waxes and Other Liquids

Degassing (deaeration, in the case of air) is the process of removin... Read more...

01/02/16

Acoustic Cavitation: The Driving Force Behind Ultrasonic Processing

Liquids exposed to high-intensity ultrasound can undergo acoustic ca... Read more...

11/03/15

4 Main Components of an Ultrasonic Liquid Processor

Are you introducing ultrasound as a new technological solution for y... Read more...

Customer Testimonials

Petri Jokiranta, Managing Director at Adpap Ltd.

“Adpap Ltd. is a pulp and paper, paint, chemical, raw material and additive process expert with clients around the world. We have been using ISM`s ISP-3000 industrial system since 2014. We have successfully implemented their equipment in several of our processes and are very satisfied with the results. ISM has been excellent in responding to questions and addressing any of our concerns. We look forward to working with them on many upcoming projects in the near future.”