Laboratory-Scale Processor

“Laboratory in Name Only”

The LSP-600 ultrasonic processor is the largest, most robust, and versatile laboratory unit on the market today. It ensures optimal value for your equipment investment by offering both R&D functionalities along with light production capabilities.

- The LSP-600 is a flexible unit that can handle a test batch with ease while providing the benchmark by which you can scale up to larger production units. Engineered to streamline the transition from R&D to commercialization, the LSP-600 is meticulously designed to be the most reliable, flexible, and user-friendly laboratory ultrasonic processor available.

- Patented Barbell Horn®-based design that can generate high amplitudes with wide range amplitude control.

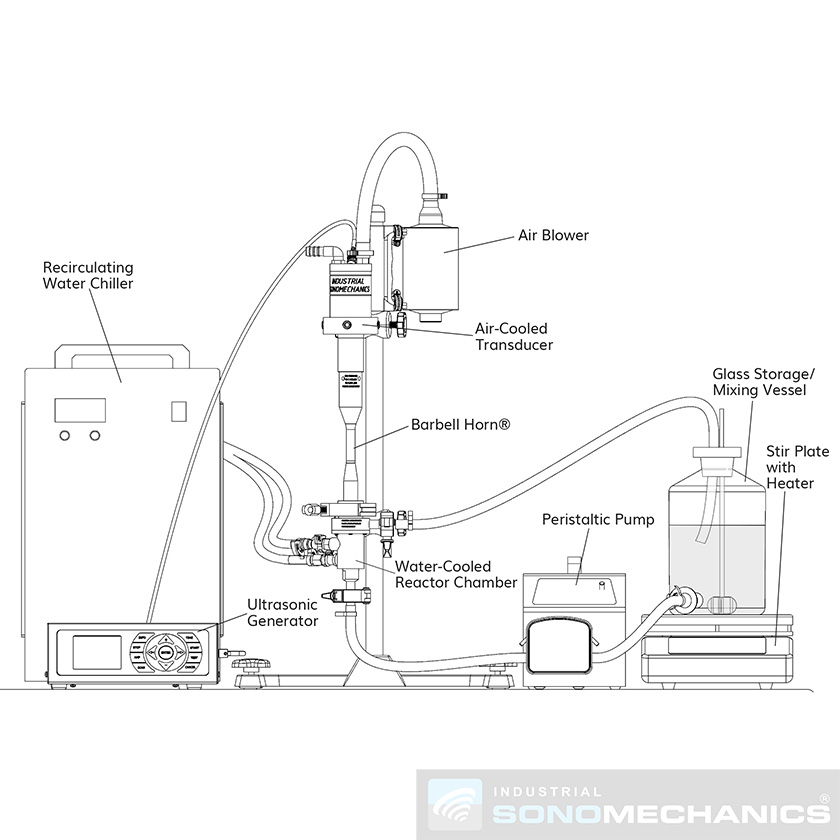

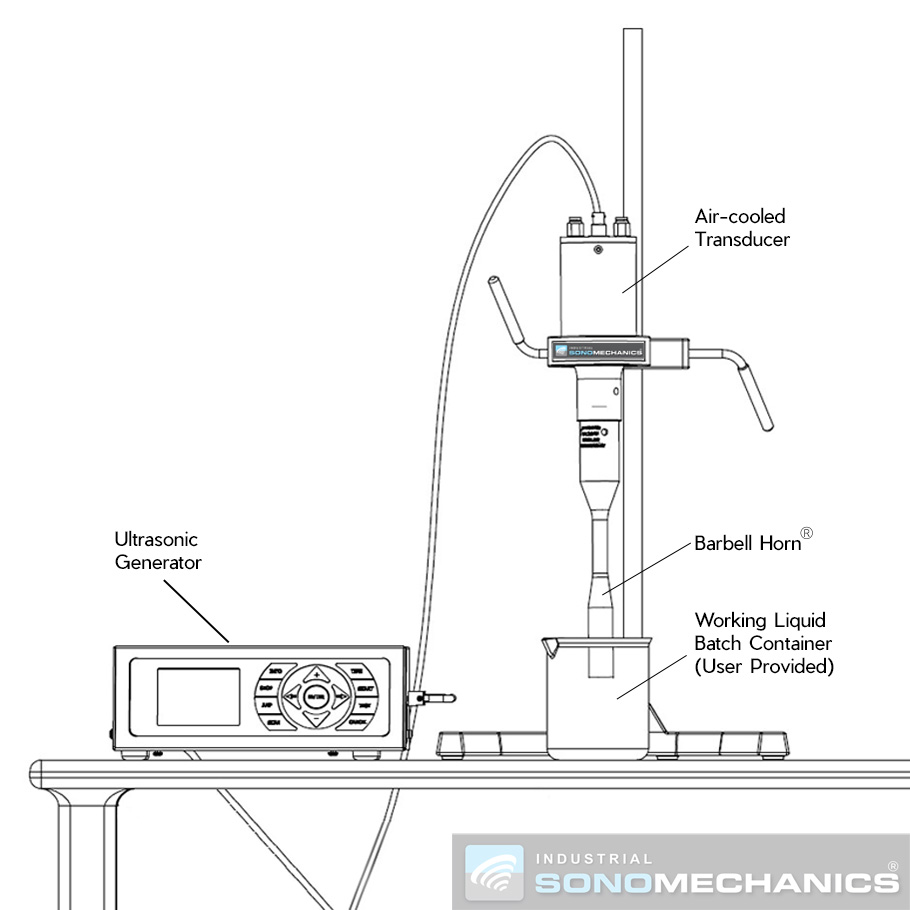

- Two configurations: batch and flow-through (refer to schematics on the left). Typical liquid material volumes for this unit range from 15 mL to 2 L at a time.

- Portable, mobile, compact, while consistently delivering big results.

- Equipped with state-of-the-art components and accessories, including NRE-30 sound enclosure, flow-through storage/mixing vessel with continuous stirring, and precise liquid material temperature control (see SPECIFICATIONS tab).

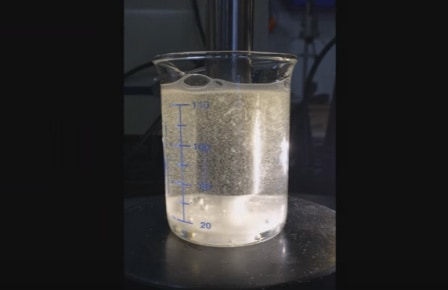

- Capable of handling various liquid materials with high solids content and wide range of viscosities.

- It is delivered worldwide and arrives mostly pre-assembled for seamless integration into your lab.

- ISM customer support team and detailed documentation are available to assist you in conquering lab experiments and scaling them up.

- The LSP-600 processor is built with cGMP compliance in mind and is used to test and formulate groundbreaking products, conduct research studies and clinical trials around the globe.

LSP-600 Features at a Glance:

Download Ultrasonic Processors Comparison Chart

Learn Why Power Rating is Meaningless & Amplitude Matters

MAIN COMPONENTS

- Ultrasonic generator (600 W)

-

Input voltage:100 Vac – 240 Vac

@ 50/60 Hz -

Rated current:10 Amps max.

- Output characteristics: 600 W (max.), 20 +/- 1 kHz (max.)

- Additional features: continuous resonance frequency lock, automatic power adjustment, fine amplitude adjustment and lock (20 – 100 %), real-time monitoring of output power and frequency, optional external control, optional pulsed operation.

-

- Air-cooled piezoelectric transducer (ACT-22-LSP)

- Output characteristics: amplitude — 22 microns (max.), frequency — 20 (+/- 1) kHz, power — 600 W (max.)

- Full-wave Barbell Horn® (FBH, 21 mm tip diameter)

- Output characteristics: amplitude — 115 μm (max), frequency — 20 (+/- 1) kHz, power — 600 W (max.)

OPTIONAL ACCESSORIES

- Flow-through reactor chamber (flow cell, 1/2″ tri-clamp inlet and outlet, cooling jacket)

- Conventional horn (CH, 12.7 mm tip diameter, amplitude — 113 microns (max.))

- Support stand with clamp holders

- Noise reduction ear muffs

- Sound enclosure

- Magnetic stirrer with hotplate

- 2 L process vessel

- Peristaltic pump

- Air blower

- Water chiller

- Glass beaker

- NanoStabilizers®

- Flow-through filters

ADDITIONAL INFORMATION

- Materials of wetted parts:

- Reactor chamber — 316 stainless steel. Food compatible.

- Horns (FBH, CH, microtips) — Ti6Al4V. Food compatible.

- Gaskets — Buna-N or Teflon. Food compatible.

- O-rings — Buna-N. Food compatible.

- Noise level:

- 103 – 106 dBa at 2′ away. Noise reducing earmuffs or sound enclosure required.

- Capacity

- 15 ml – 100 ml — with CH (batch mode)

- 100 ml – 500 ml — with FBH (batch mode)

- 500 ml – 2 L — with FBH + reactor chamber (flow-through mode).

- Productivity rates

- Productivity rates are highly dependent on the nature of each process and range from about 200 mL/h for challenging tasks (e.g., top-down nanocrystallization of active pharmaceutical compounds) to over 10 L/h for fast processes (e.g., degassing, deagglomeration).