ISM was created in 2006 to commercialize its patented Barbell Horn® Ultrasonic Technology (BHUT). Today our equipment is sold all over the world and we are best known for our ability to scale-up ultrasonic processors without sacrificing the vibration amplitudes and cavitation intensities, which is the only way one can maintain consistent product quality on a large scale.

Some of our history

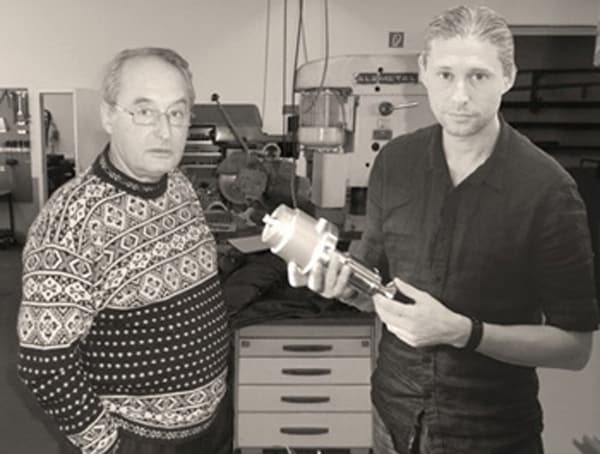

Almost 20 years ago, Dr. Alexey Peshkovsky left his academic research position in medical physics and joined his father, Dr. Sergei Peshkovsky, in founding Industrial Sonomechanics (ISM). ISM was formed in New York, NY in 2006, after the invention of the Barbell Horn®: a device that permits scaling up ultrasonic processors without sacrificing the vibration amplitudes and cavitation intensities they are able to generate. The scale-up is accomplished without changing any of the optimized parameters, and therefore, the process is guaranteed to generate the same results on the plant floor as it does in the laboratory. The Barbell Horn® design principles were developed by the company’s co-founder, Dr. Sergei Peshkovsky, during several decades of research and development in Russia. Dr. Sergei Peshkovsky was a prominent scientist in the field of ultrasound theory and engineering, in which he patented more than 20 discoveries and inventions, wrote over 50 publications and published several books. Together with Dr. Alexey Peshkovsky, ISM’s current President and Chief Scientific Officer, the two have created a company that has become a leading R&D, equipment design and process consulting firm in the field of high-intensity ultrasonic technology for liquid treatment.

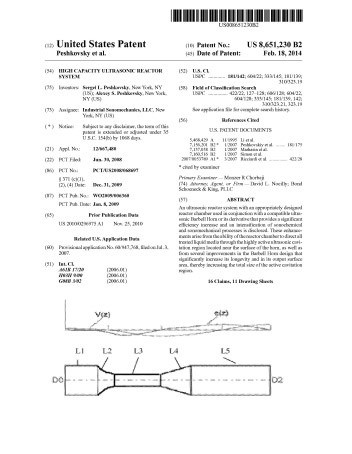

Patents

Intellectual property rights are vital to our company. ISM’s first patent for its ultrasonic resonant rod waveguide-radiator was filed in 2006 (granted in 2007) and introduced the first generation Full-wave Barbell Horn® – a device that permits scaling up ultrasonic processors without sacrificing the vibration amplitudes and cavitation intensities, which was previously impossible with conventional ultrasonic horns. Our second patent on high-capacity ultrasonic reactor system was filed in 2007 (granted in the U.S. in 2014) covering major improvements in the company’s Barbell Horn® Ultrasonic Technology (BHUT) – improvements to the Full-wave Barbell Horn®, introduction of a new horn type – the Half-wave Barbell Horn®, and our new Reactor Chamber design. “This patent is an essential component of our intellectual property portfolio,” said Dr. Alexey Peshkovsky. “It delivers a much-awaited breakthrough in the field of industrial-scale ultrasonic liquid processing, which is critical for a wide variety of applications.” In 2012, ISM filed its third patent (granted in 2015) for efficient cooling of piezoelectric transducers, which, together with the first two, has become the core of our Barbell Horn® Ultrasonic Technology. “Our technology is free from scale-up limitations of conventional ultrasound, making it possible to implement laboratory accomplishments in the production environment”, said ISM’s Commercial Director, Jeffrey Meyer. “We are confident that ISM’s patent portfolio, combined with its know-how, will provide our products with long-term market exclusivity.”

What is ISM today

Today ISM is a leading R&D, equipment design and process consulting firm, specializing in high-intensity ultrasonic technology for liquid treatment. Our goal is to help businesses optimize their ultrasound-assisted processes and implement them in commercial-scale production. The company brings together substantial expertise in ultrasonic engineering and liquid processing. We are engaged in active research in multiple areas of ultrasonic technology application, including the production of nanoemulsions, nanocrystals and liposomes for the pharmaceutical, cosmetic, food, nutraceutical, printing ink, paint, coating, wood treatment, metalworking, nanocomposite and fuel industries, as well as waste water purification, plant oil extraction, production of biofuels, crude oil desulphurization, viscous liquid degassing, cell disruption, nano-scale dispersing, and many more.