With the use of ultrasonic reactor chambers (flow cells), ISM’s ultrasonic systems can be configured for continuous sonochemical liquid processing in a “flow-through” mode (see below). When a large amount of material needs to be processed, this arrangement is preferable to the “batch”

For detailed information download our

Continuous Ultrasonic Liquid Processing

- can be configured for continuous sonochemical liquid processing in a “flow-through” mode (see below).

- preferable to the “batch” mode because it results in a much higher processing capacity, improved ultrasonic exposure uniformity and better temperature stability.

- During continuous ultrasonic processing, ensures that all working liquid is directed through the active cavitation zone(s) created by the incorporated Barbell horn

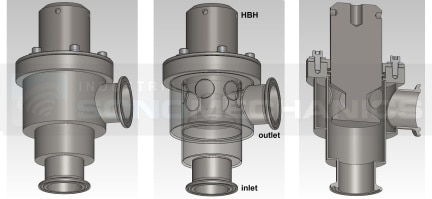

Bench-Scale Reactor Chamber

- output diameter of the horn is commonly in the range of 30 – 33 mm, and the internal volume of the assembly is about 80 ml.

- may be used with any Barbell horn type.

- penetration of the horn into the chamber is arranged such that the non-vibrating mounting flange on the horn is “sandwiched” between

- which processed liquid is supplied through the “inlet” and collected through the “outlet” sanitary flanged connections

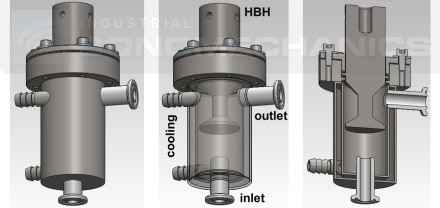

Industrial-Scale Reactor Chamber

- output diameter of the horn is commonly 47 – 50 mm and the internal volume of the assembly is 250 – 300 ml.

- Larger horn diameters and reactor chamber volumes are available upon request.

- same reactor chamber may be used with any Barbell horn type.

- Recirculating configuration

- Single-pass configuration

- Multi-reactor configuration